In the modern era, the power of technology isn't just about automation or digitization. It's about intelligence, innovation, and integration. Two of the most transformative technologies impacting asset-heavy industries today are Artificial Intelligence (AI) and Digital Twins.

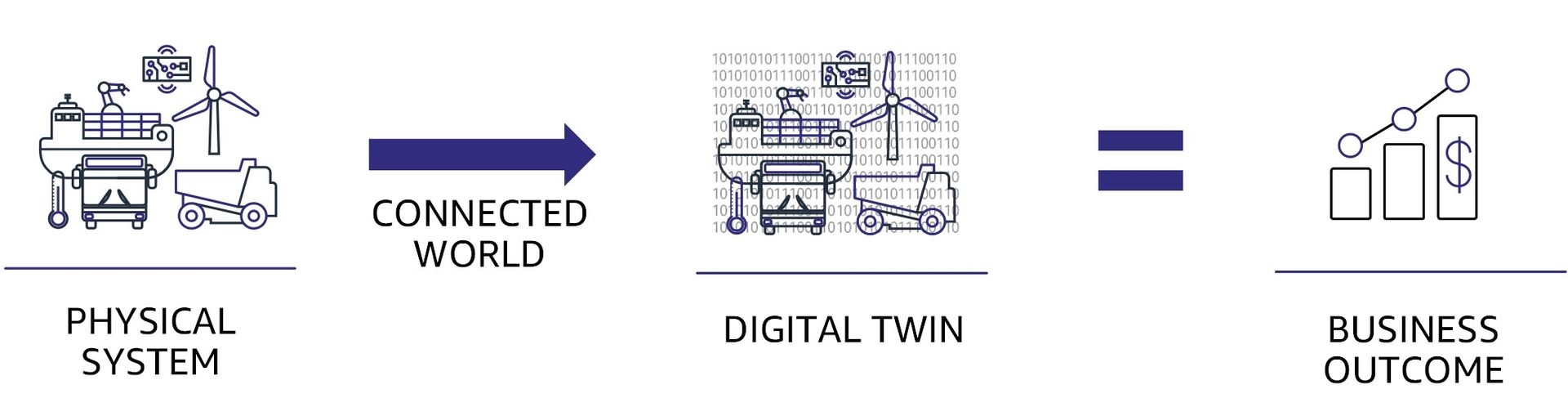

Digital Twins: Virtual Mirrors of the Physical World

AI: The Brain Behind the Operation

The Powerful Duo: AI and Digital Twins

Predictive Maintenance

Predictive maintenance is one of the key benefits of digital twin technology. By creating a digital twin of a physical asset, manufacturers can monitor and analyze performance data in real-time. This enables them to identify potential issues before they become major problems, and schedule maintenance proactively to prevent downtime.

Through the use of AI and machine learning algorithms, digital twin technology can also anticipate future maintenance needs and automatically schedule repairs or replacements as necessary. This not only helps to reduce downtime, but also extends the life of assets and reduces overall maintenance costs.

Predictive Analytics

Predictive analytics is another key benefit of digital twin technology. By combining real-time performance data with historical data and external factors such as weather patterns, manufacturers can gain insights into future trends and potential issues that may affect performance.

Through the use of AI and machine learning, digital twin technology can also help manufacturers anticipate future demand and adjust production schedules accordingly. This can help to reduce waste and improve overall efficiency.

Enhanced Data Analysis

Digital twin technology enables manufacturers to collect and analyze vast amounts of data in real-time. This includes data on asset performance, operational efficiency, and supply chain logistics. By leveraging AI and machine learning algorithms, manufacturers can gain deeper insights into this data and identify patterns and trends that may be difficult to detect otherwise.

Improved data analysis can help manufacturers to optimize processes, reduce waste, and improve overall efficiency. It can also help to identify areas for improvement and drive innovation.

Improved Decision-making

By providing real-time data on asset performance, operational efficiency, and supply chain logistics, digital twin technology enables manufacturers to make data-driven decisions. This can help to improve overall efficiency and reduce costs.

Through the use of AI and machine learning algorithms, digital twin technology can also help manufacturers to anticipate potential issues and adjust processes to prevent them from occurring. This not only helps to reduce downtime, but also improves product quality and reduces defects.

Industry-Specific Use Case

Manufacturing

Energy

Aquafarming

Fleet Management

Retail

AI can analyze data from digital twins of physical stores to optimize layouts, manage inventory efficiently, and personalize the customer experience.

Insurance

Digital twins can simulate diverse scenarios for risk assessment, and AI can use these simulations to price premiums accurately, detect fraudulent claims, and streamline the claims process.

Real Estate

By creating digital twins of properties, real estate companies can give virtual tours to potential buyers. AI can enhance this experience by personalizing tours based on the buyer's preferences and providing predictive maintenance alerts for the property.

Empowering Industries through AI and Digital Twins